Shell/Tire Replacement

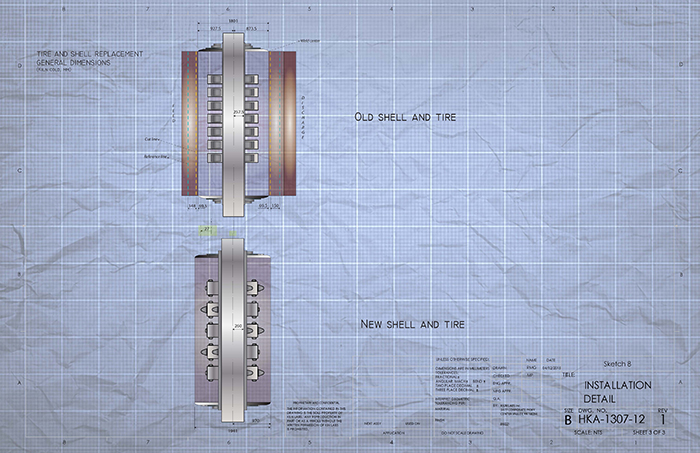

Installation details and procedure for replacement of tire and shell section. Re-alignment of shell and field installation supervision

Installation details and procedure for replacement of tire and shell section. Re-alignment of shell and field installation supervision

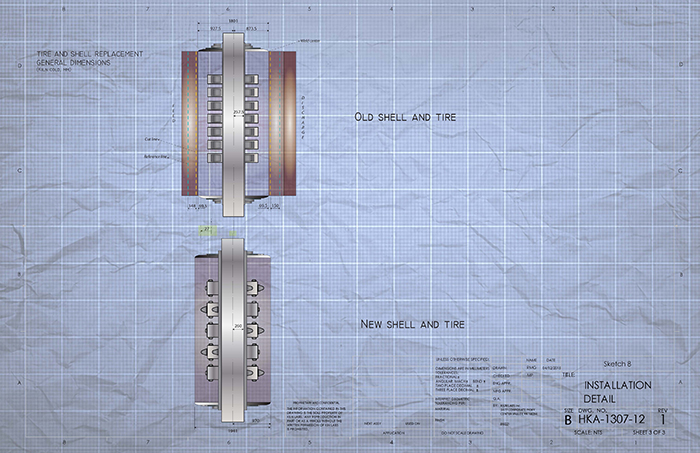

Discharge Shell modification including new design with cowling.

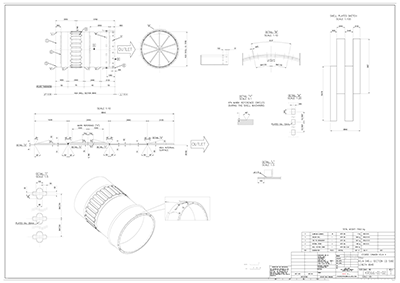

Shell Bending Stress Analysis, dynamic and static.Concentrated and distributed loads at girth gear and bearings (Hertz) pressure.

Modification of tire shell section, including new tire pads design.

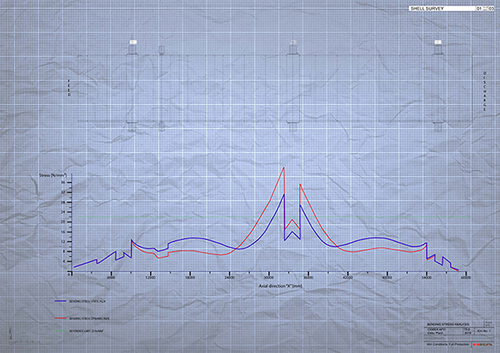

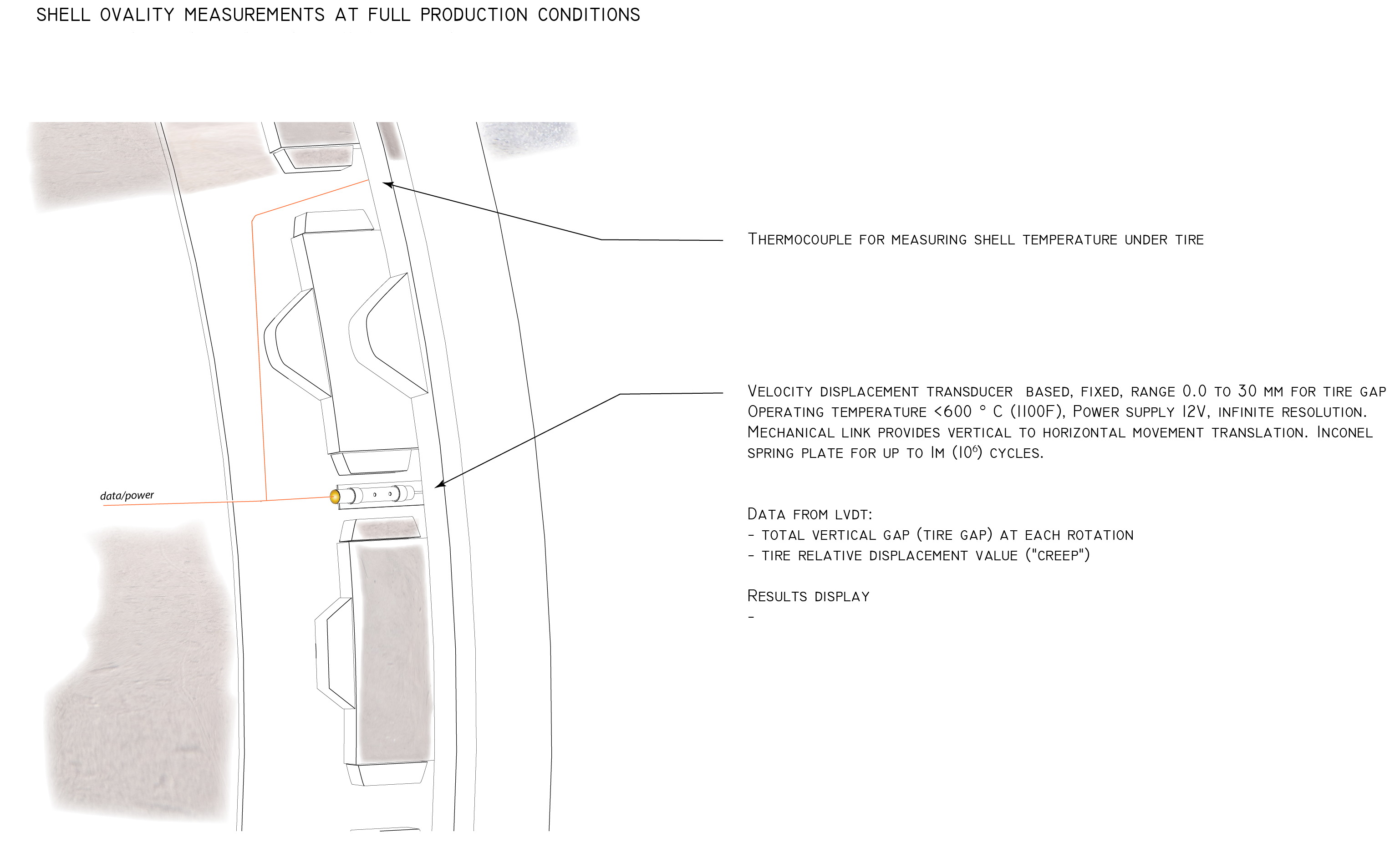

LVDT based instrument for reliable measurements of shell ovality under tire. For up to 600℃ [1100F] operation. Non destructive installation.

Inductive sensor based instrument for reliable measurements of gear meshing (root clearance). For maximum 40 mm of radial runout. Fixed installation.

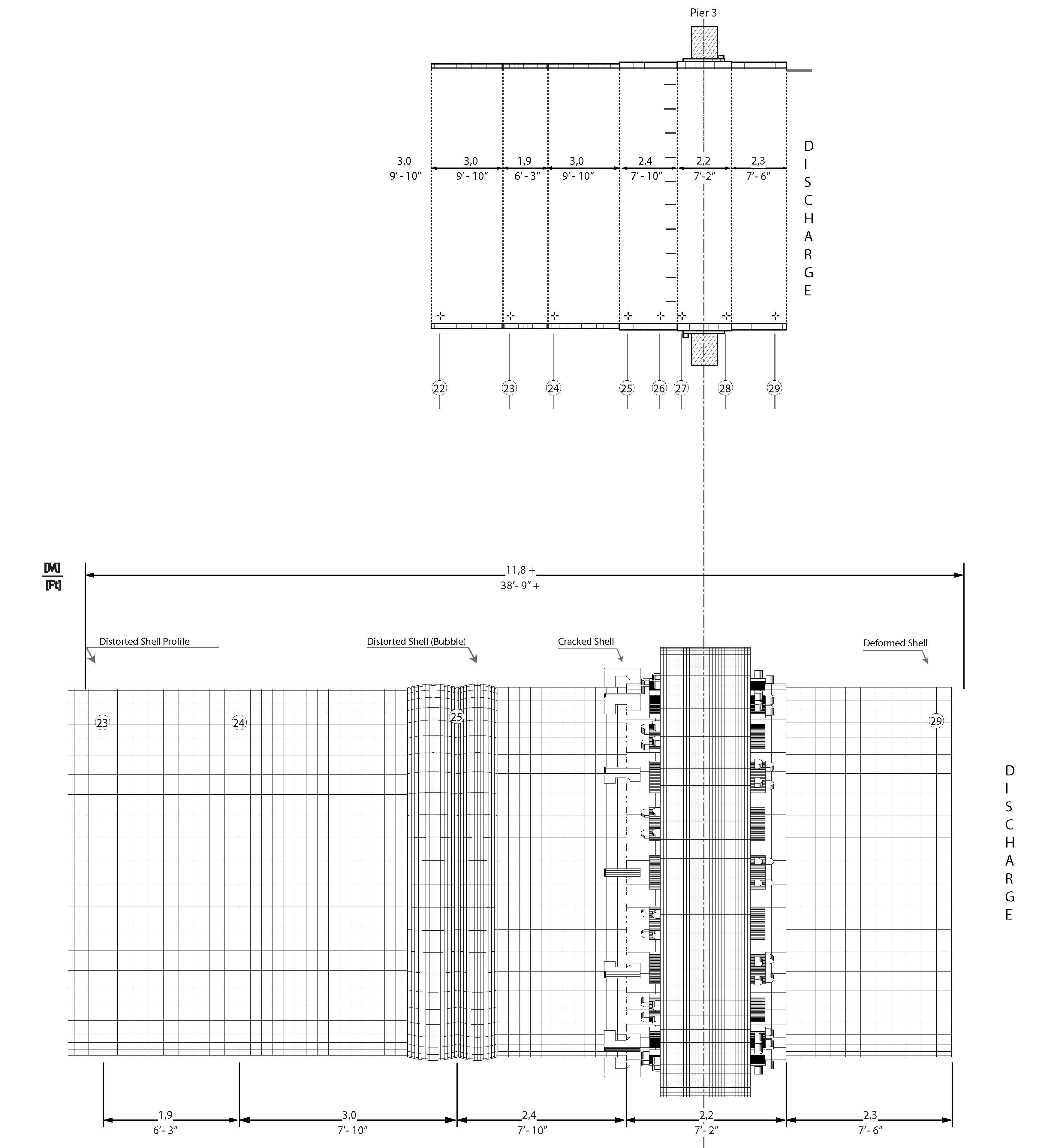

Evaluating shell deformations, simulating replacement, choosing cut lines location, supervisisng shell changout re-alignment, preparing shell for welding.